Description

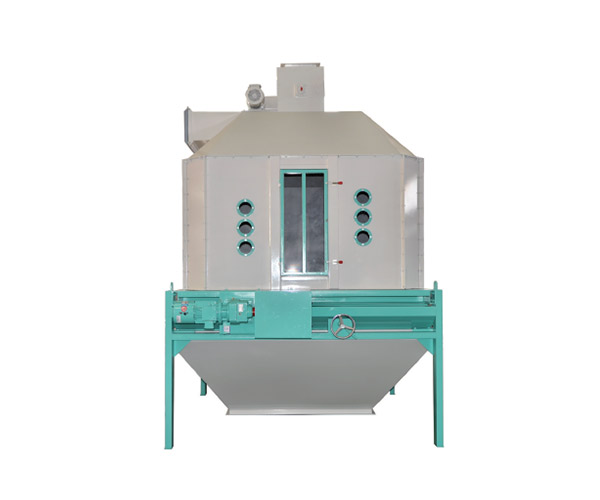

- The counter flow cooler principle is applied to cool the pellets with high temperature and moisture. This is to avoid the pellets from cracking which is caused by a sudden change in temperature. Hot air will touch the hot pellets with high moisture while cool air will touch the cooled pellets with lower moisture.

- The top cover is made of stainless steel structure, adjustable rhombic spreader which results in an even distribution of the pellets.

- Air enclosed feeder is applied for the feeds to avoid the air passing from the feed inlet. This results in a good cooling effect.

- Upper and lower level indicators are utilized to control the cooling process automatically.

- Slide reciprocating discharger is used for smooth and reliable discharging.

| Model | SKLN 16 x 16 | SKLN 20 x 20 | SKLN 22 x 22 | SKLN 24 x 24 | SKLN 26 x 26 | SKLN 24 x 30 |

|---|---|---|---|---|---|---|

| Cooling Volume (m3) | 3 | 5 | 7 | 8 | 10 | 12 |

| Capacity (TPH) | 5 | 10 | 15 | 20 | 25 | 30 |

| Cooling Time (min) | 10 - 15 | 10 - 15 | 10 - 15 | 10 - 15 | 10 - 15 | 10 - 15 |

| Product Temperature after Cooling | + 3 - 5 | + 3 - 5 | + 3 - 5 | + 3 - 5 | + 3 - 5 | + 3 - 5 |

| Air Absorbing Volume (m3/min) | 34 | 34 | 34 | 34 | 34 | 34 |

| Power (kw) | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 |

| Power of Airlock (kw) | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 | 1.1 |